Drilled and Slotted Brake Rotors Collection

- Featured

- Best selling

- Alphabetically, A-Z

- Alphabetically, Z-A

- Price, low to high

- Price, high to low

- Date, old to new

- Date, new to old

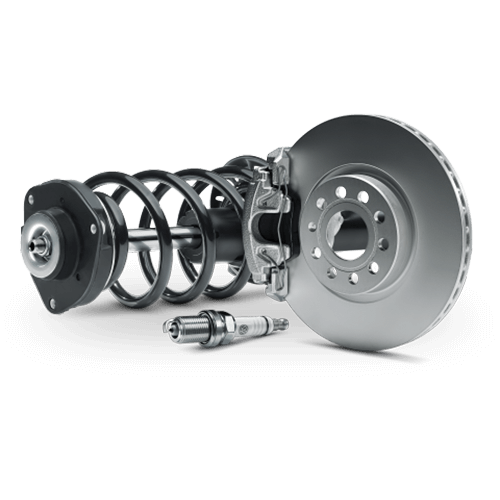

Drilled and Slotted Brake Rotors Collection

Upgrade your vehicle's braking performance with our premium selection of drilled and slotted brake rotors. Engineered to deliver superior stopping power, these performance rotors combine the benefits of both drilled brake rotors and slotted brake rotors into one advanced design.

Understanding Performance Rotor Technology

Drilled brake rotors feature precision-engineered holes that enhance heat dissipation and channel away water, gases, and debris from the braking surface. This design significantly reduces brake fade during demanding driving conditions while improving wet weather performance. The strategic hole placement maximizes cooling efficiency, making drilled rotors ideal for daily drivers and performance vehicles.

Slotted brake rotors incorporate machined grooves that continuously clean the pad surface and expel hot gases generated during braking. These slots provide consistent friction and exceptional durability, with greater resistance to cracking compared to standard rotors. When comparing slotted brake rotors vs regular smooth rotors, the slotted design delivers noticeably improved bite and reduced brake fade under heavy loads.

Are Slotted Brake Rotors Better?

The answer depends on your driving needs. Our drilled and slotted rotors combine both technologies, offering optimal heat management, effective debris removal, and enhanced braking consistency. This hybrid design excels in diverse conditions - from highway driving to towing heavy loads - making them a versatile upgrade for trucks, SUVs, and performance cars.

Browse our collection of quality drilled and slotted brake rotors from trusted manufacturers. Each rotor meets rigorous safety standards to deliver reliable, long-lasting braking performance across Canadian roads.